FLECS provides an app store for PLCs and Edge devices. FLECS Technologies is a young company from the Allgäu region in Germany and is behind the open-source project FLECS. FLECS is available for all Linux based systems or virtual machines and offers full transparency and customizability.

Interview with Samuel Greising, Managing Director & COO at FLECS Technologies GmbH.

Easy Engineering: What are the main areas of activity of the company?

Samuel Greising: FLECS makes the world’s automation solutions available in one place, with just one click!

It gives the machine manufacturer a whole new way to set up their automation system – and discover solutions that will give them a decisive edge.

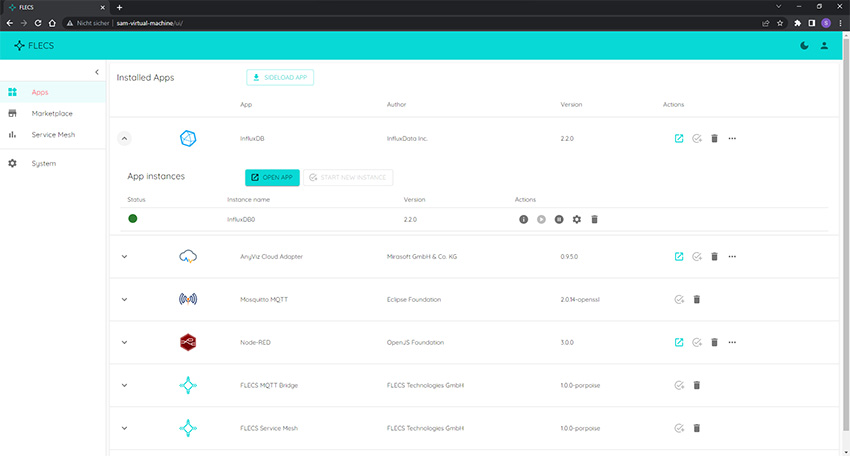

Installing or updating applications on the control system (PLC) costs machine manufacturers a lot of time and money. FLECS automates this process. Thus, FLECS offers machine manufacturers the possibility to use hardware-independent software programs for any automation task quickly and easily.

Apps are installed, monitored and kept up to date via the application layer. The service mesh provides a communication layer that allows all apps to talk to each other. For PLC manufacturers, this also means that the “batch size 1 PLC” can come.

In many cases, machine manufacturers and operators have to expand and retrofit their machines and systems. Here, too, FLECS provides support by installing the system on so-called edge devices and a wide range of apps for connectivity with controllers from different manufacturers such as Siemens, Rockwell Automation or Schneider Electric. Via the service mesh, the PLC data is immediately available to the apps on the edge device.

Machine manufacturers thus save 40% time in engineering and maintenance compared to the previous approach.

E.E: What’s the news about new products?

S.G: We release a new version every six weeks, which users can install or update very easily. This allows us to evolve quickly and in line with customer needs. Most recently, we were able to implement incredible performance increases in our service mesh. In addition, new third-party apps and new PLC or Edge devices with native support for FLECS are constantly appearing.

We are currently working on a solution that will make it easier for machine manufacturers to transfer apps and settings from one machine to the next. This will further save time when setting up their machines.

E.E: What are the ranges of products?

S.G: The focus is on the equipment of new machines but also on retro-fit with the help of edge devices. In addition to machine building, FLECS is used in intralogistics, building automation and mobile machines.

As you can see, FLECS addresses a generic problem faced by automation companies in a wide variety of industries. Of course, this makes it incredibly exciting for us, and at the same time it conceals a huge potential.

Samuel Greising, Managing Director & COO at FLECS Technologies GmbH.

©Tobias_Hertle

E.E: At what stage is the market where you are currently active?

S.G: The market for automation is very fragmented and set. Established players have built up small monopolies in their niches. However, this is becoming less and less accepted by users and the market is starting to shake out from there. The dependencies that have been established here have been the undoing of some due to supply chain problems and the general global situation.

E.E: What can you tell us about market trends?

S.G: Interoperability, flexibility and security are becoming increasingly important. This is not possible to implement with the current systems and business models. This is exactly where we come in and offer completely new possibilities and business models with our completely new approach.

That is why many PLC manufacturers are approaching us to secure their positions and also to open up new markets.

E.E: What are the most innovative products marketed?

S.G: Today, as we can see from the title of this magazine “Easy Engineering”, complex issues must be presented simply for the user. This is exactly what we have committed ourselves to. It is a special honour for us that we have been nominated by a professional journal as one of the most innovative products of 2023. With FLECS, we are in a prominent environment with Bosch, Siemens and Weidmüller, among others.

E.E: What estimations do you have for 2023?

S.G: Our goal is to convince as many PLC and edge device manufacturers as possible to bring FLECS to their devices. This way we want to increase our reach and enable as many machine manufacturers as possible to operate future-proof automation. At the same time, more and more app vendors want to offer their apps with us, as they increase the reach of their apps with each new compatible device. We make this possible through a very simple onboarding process for new apps.