Small space, different machining phases, and a pleasing design – Metal Work’s demands for Brembo’s demo line for the Polytechnic University in Milan were high. In the Swiss company Montech, the integrator Metal Work found just the right partner to satisfy the requirements of the world’s leading manufacturer of braking systems and components, Brembo.

In the motorized world, no one can overtake Brembo. This Italian company is a world leader in the design, development, and production of braking systems and components for cars, motorcycles, and industrial vehicles for the original equipment market, spare parts, and racing. Brembo is happy to pass on its expertise to future engineers. To this end, it set up a demonstration line in collaboration with the integrator Metal Work for the Polytechnic University in Milan, one that shows how processing phases are performed.

High demands and difficult requirements

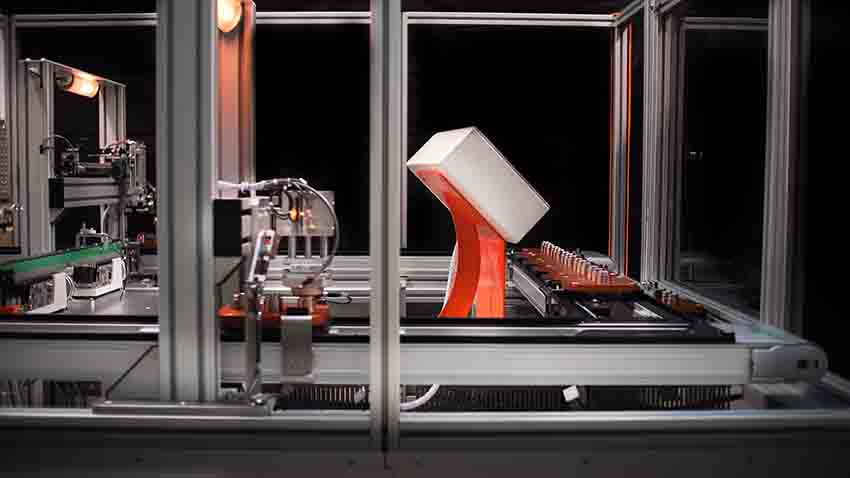

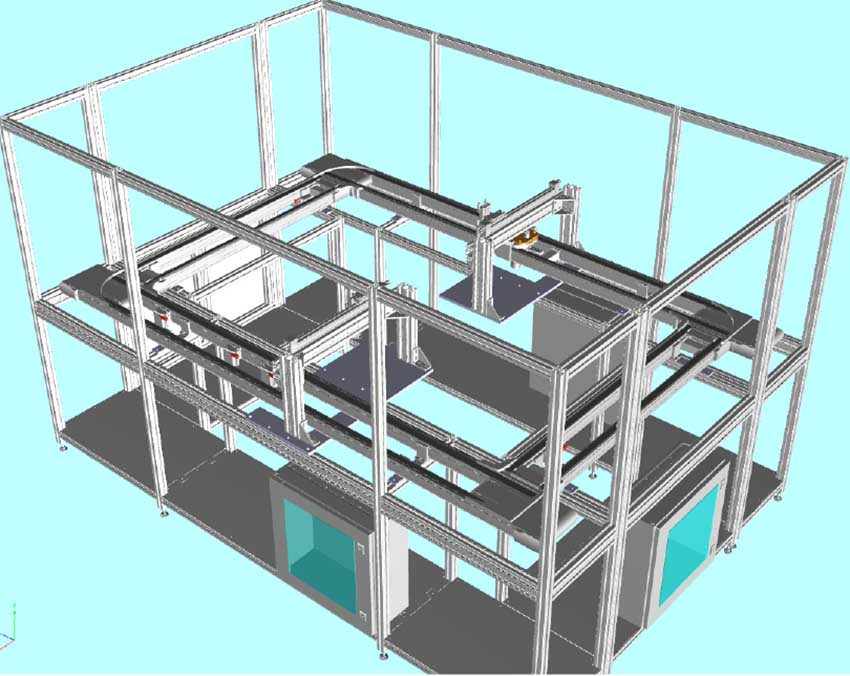

The requirements for the implementation of the demo line were difficult, the demands were high: Metal Work wanted four machining steps for the line. It should also have centering processes and flexible lines. However, the available space was very small. And, of course, a clean, aesthetic design was a “must” – because for Metal Work and Brembo, the demo line has more than an educational purpose; it represents these companies.

Standard solution, customized

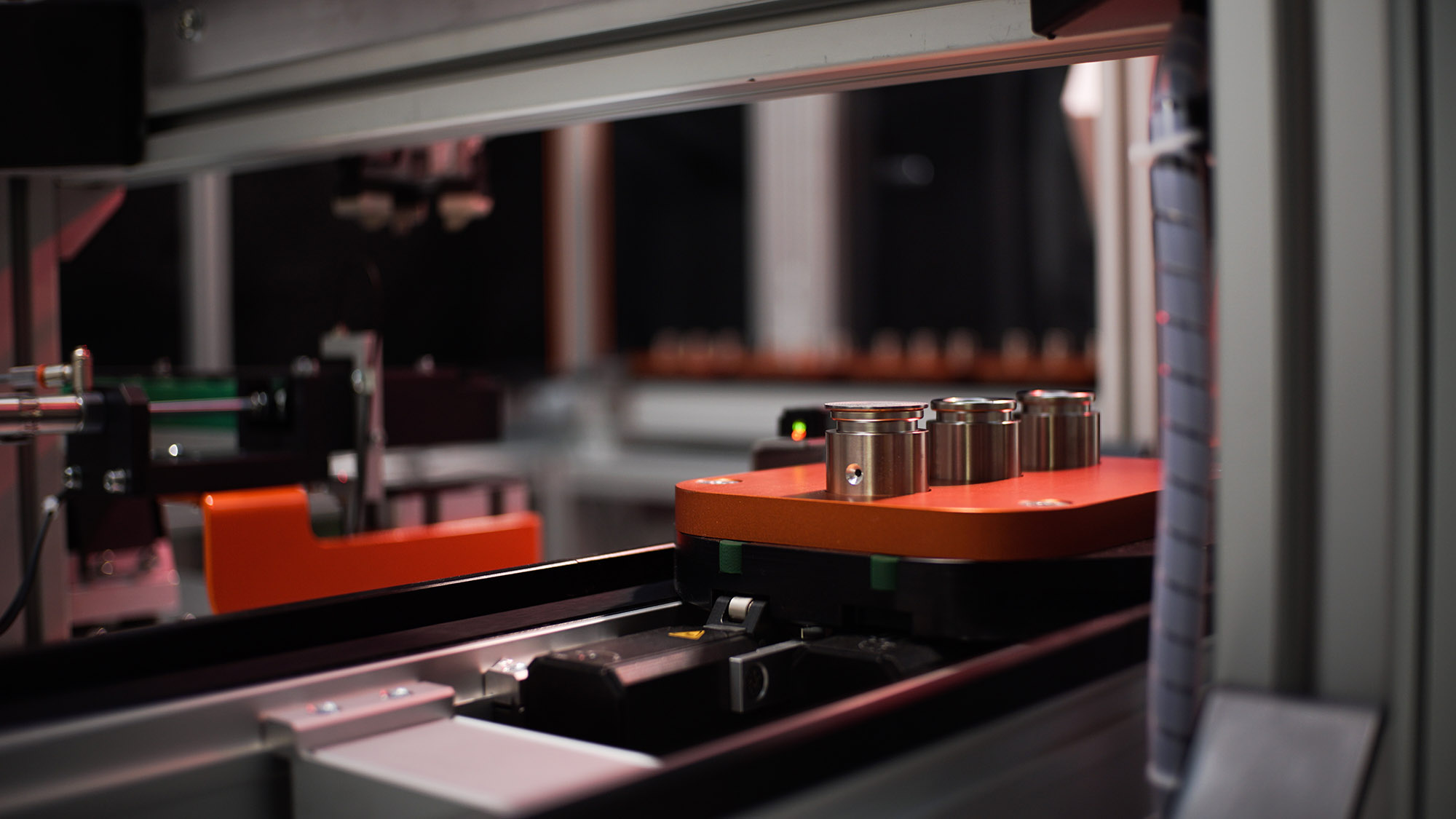

Metal Work found just the right address at Montech. The Swiss technology company specializes in the industrialization and standardization of state-of-the-art, unusual belt conveyors, transfer systems, and innovative aluminum framing systems. For the demo line, Montech reworked the standard pallets of the LT40 transfer system individually.

There are three stoppers in each of the four processing stations. This allows the pallet to be stopped and moved step by step, which has the advantage of machining several parts in each workstation: If the parts are positioned on a single pallet, the same operation can be performed on three different parts.

Functional and aesthetic – the LT40

Montech’s LT40 transfer system satisfied Metal Work with regard to function, structure, and aesthetics. It can easily carry small parts in the various machining phases and the integrated brushless motor allows a compact design, which is ideal especially in tight spaces. In addition to maximum space utilization, the 24 V motor also offers flexible parameter management. With analog signals, changes in speed and direction are possible. And with its clear, slim design, the LT40 offers the desired aesthetic to represent Brembo in appropriate fashion.

The result, as well as the service from Montech, won Metal Work over all down the line: The line was pre-assembled, tested, and delivered according to customer requirements – and delivery was very quick.